Welcome to BBN Steel Materials Factory

20CrMo Alloy Steel

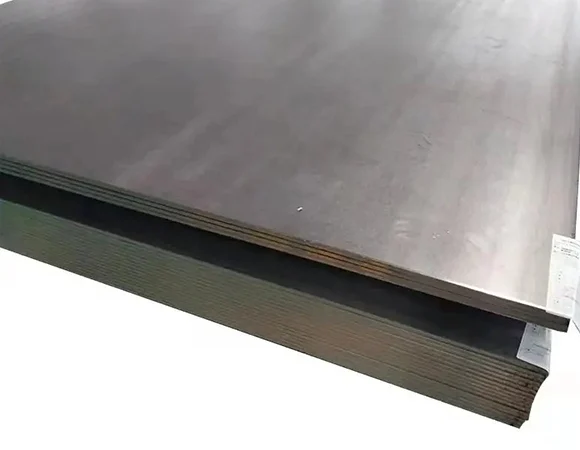

GB/T 3077 20CrMo alloy steel material 20CrMo alloy structural steel

FOB Reference Price: Get Latest Price

Description: 20CrMo steel is a chromium-molybdenum alloy steel plate with high strength, high hardness, good toughness, small quenching deformation, high temperature creep strength, high durability strength, cold strain plasticity, good machinability and weldability. ...

Processing Service: Cutting, Welding, Drilling, Rolling, Bending, Forming, Grinding, Stamping and so on machining

Available Size: Thickness: 4-100mm, Width: 900-4700mm, Length: 5000-18000mm

20CrMo Alloy Steel Description

20CrMo steel is a chromium-molybdenum alloy steel plate with high strength, high hardness, good toughness, small quenching deformation, high temperature creep strength, high durability strength, cold strain plasticity, good machinability and weldability. 20CrMo is used to manufacture non-corrosive media in chemical equipment and high-pressure pipelines, fasteners, steam turbines, boiler blades and forgings with working temperatures below 250 ° C, as well as important carburized parts such as gears and shafts in general machinery.

20CrMo alloy structural steel plate with high hardenability, no temper brittleness, good weldability, little tendency to form cold cracks, good machinability and cold strain plasticity. The 20CrMo alloy steel material is mainly used to manufacture important parts such as gears, shafts, connecting rods, and crankshafts. According to different heat treatment processes, 20CrMo alloy steel materials can be divided into quenching and tempering, normalizing and tempering, quenching and tempering and low temperature tempering, etc.

1. Quenching and tempering: Heating the 20CrMo alloy steel material to a certain temperature, then quenching in water or oil, and then tempering at a temperature lower than the quenching and tempering temperature.

2. Normalizing and tempering: Heat the 20CrMo alloy steel material to a certain temperature, air cool it, and then temper it at a temperature lower than the quenching and tempering temperature.

3. Quenching and tempering plus low-temperature tempering: Heating the 20CrMo alloy steel material to a certain temperature, then quenching with water or oil, and then low-temperature tempering after tempering.

20CrMo alloy steel has suitable hardenability, and after suitable metal heat treatment, the microstructure is uniform sorbite, bainite or very fine pearlite, so it has high tensile strength and yield strength. Ratio (generally around 0.85), high toughness and fatigue strength, and low toughness-brittle transition temperature, can be used to manufacture machine parts with large cross-sectional dimensions, and are widely used in various industries. During use, it is necessary to do a good job of heat treatment according to the different properties of 20CrMo alloy steel materials.

20CrMo Alloy Steel Datasheet

Thickness: 1.2-250mm (2-100mm usually used)

Width: 900-4200mm (1000-2200mm usually used)

Length: 5000-18000mm or as your request

Surface: Clean, finishing,blasting and painting according to customer requirement

Certificate: API, ISO, SGS, BV, CE etc

Quality: MTC will be provided with goods, third part inspection is acceptable

20CrMo Alloy Steel Chemical composition

| Grade | C | Si | Mn | Cr | Mo |

|---|---|---|---|---|---|

| 20CrMo | 0.17-0.24 | 0.17-0.37 | 0.4-0.7 | 0.8-1.1 | 0.15-0.25 |

20CrMo Alloy Steel Mechanical Properties

| Grade | Tensile strength | Yield strength | Reduction % | Elongation A% |

|---|---|---|---|---|

| 20CrMo | 885 | 685 | 50 | 12 |

Equivalent Grade of 20CrMo Alloy Steel

| GB | USA | Germany | JIS | France | UK | ISO |

|---|---|---|---|---|---|---|

| 20CRMO | ASTM A29/A29M 4120 | 25CrMo4 (1.7218) | JIS G4053 SCM420 | NF EN 10083-3, NFA35-551 |

BS EN 10083-3, BS 970 Part 1 |

ISO 683-1 18CrMo4 |

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Leave a Message