Welcome to BBN Steel Materials Factory

Gr1 Titanium Alloy Materials

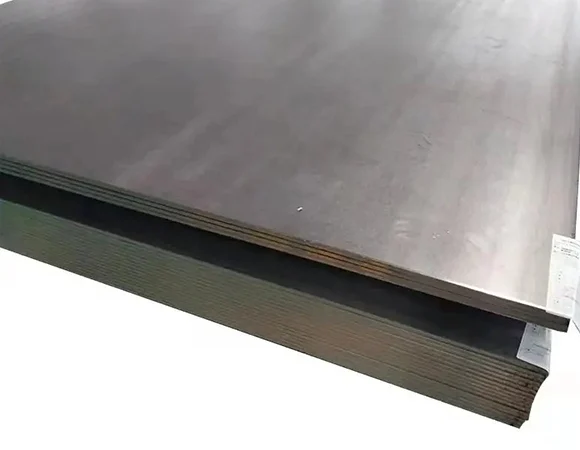

Gr1 Titanium Alloy Sheet Strip and Rod

FOB Reference Price: Get Latest Price

Description: GR1 is industrial pure titanium. Dense metallic titanium with a titanium content of not less than 98% and containing a small amount of impurities such as oxygen, nitrogen, hydrogen, carbon, silicon and iron. GR1 titanium alloy is a pure titanium material ...

Processing Service: Cutting, Welding, Drilling, Rolling, Bending, Forming, Grinding, Stamping and so on machining

Available Size: Thickness: 4-100mm, Width: 900-4700mm, Length: 5000-18000mm

Gr1 Titanium Alloy Materials Description

GR1 is industrial pure titanium. Dense metallic titanium with a titanium content of not less than 98% and containing a small amount of impurities such as oxygen, nitrogen, hydrogen, carbon, silicon and iron. . GR1 titanium alloy is a pure titanium material widely used in aerospace, medical devices, chemical industry and other fields. Its processing is challenging. Here are some common processing issues for GR1 titanium alloy:

1. Cutting: Cutting of GR1 titanium alloy usually requires the use of carbide cutting tools, and maintaining appropriate cutting speed and feed rate to reduce tool wear and improve processing efficiency.

2. Drilling: When drilling titanium alloy, select appropriate drill materials and geometric structures to ensure sufficient rigidity and cutting stability, while carefully controlling cutting parameters to avoid overheating damage.

3. Milling: When milling GR1 titanium alloy using appropriate milling processes and tools, it is important to choose the feed rate and cutting depth appropriately to avoid excessive heat accumulation, which can lead to tool wear and workpiece deformation.

4. Welding process: GR1 titanium alloy is usually welded using TIG (argon arc welding) or electron beam welding under inert gas protection. During the welding process, it is necessary to control the welding parameters to avoid problems such as oxidation and nitriding.

5. Heat treatment: GR1 titanium alloy can improve its mechanical properties and corrosion resistance through heat treatment. Common heat treatment methods include aging treatment and solution treatment.

Gr1 Titanium Alloy Materials Datasheet

Specification:

Plate/Sheet: Thickness: 0.1mm-50mm, Width:800-3000mm, Length ≤ 12000mm

Round Bar: Diameter:3.0 ~ 350mm Length: Max 6000mm

Tube&Pipe: Outer Diameter: 0.1mm-8.0mm, Thickness: 0.05mm-2.0mm

Technical standards for Gr1/TA1 Titanium alloy materials:

GB/T3620.1-2016 Titanium and titanium alloy grades and chemical compositions

GB/T 3621-2007 ASTM/B265 Titanium and titanium alloy plates

GB/T2965 -2007 ASTM/B348 titanium and titanium alloy rods

GB/T 3624-2010 ASTM337 titanium and titanium alloy seamless pipes

GB/T16598-2013 ASTM381 Titanium and titanium alloy tubes for heat exchangers and condensers

GB/T13810-1997 AMST/F136 Titanium and titanium alloy processing materials for surgical implants

GB/T3623-2007 AMST/B863 Titanium and titanium alloy wire

ASTM/B265 ASME/SB265 titanium and titanium alloy strips and foils

Gr1 Titanium Alloy Materials Chemical composition

| Grade | Chemicai composition(WT%) | ||||||

|---|---|---|---|---|---|---|---|

| Gr.1(TA1) | Ti | Fe | C | N | H | O | Other |

| ≤98 | ≤0.20 | ≤0.08 | ≤0.03 | ≤0.015 | ≤0.18 | ≤0.40 | |

Gr1 Titanium Alloy Materials Mechanical Properties

1. Mechanical properties: - Tensile strength: The tensile strength of GR1 titanium alloy is usually between about 240 MPa and 370 MPa, depending on the specific manufacturing process and heat treatment conditions. - Yield strength: usually between 140 MPa and 280 MPa. - Elongation: The elongation of GR1 titanium alloy is generally between 20% and 35%.

2. Physical properties: - Density: The density of GR1 titanium alloy is about 4.51g/cm³, which is low and conducive to weight reduction. - Melting point: Its melting point is about 1660°C, which belongs to high melting point metal and has good high temperature stability. - Thermal conductivity: about 21.9 W/(m·K), with good thermal conductivity. - Thermal expansion coefficient: The linear expansion coefficient of GR1 titanium alloy is about 8.6×10^-6 /K, and the thermal expansion performance is moderate.

Equivalent Grade of Gr1 Titanium Alloy Materials

| USA ASTM/ASME |

China GB |

Main alloy components (balance: titanium) |

|---|---|---|

| Gr.1 | TA1 | titanium |

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Leave a Message