Welcome to BBN Steel Materials Factory

15CrMo Round Bar

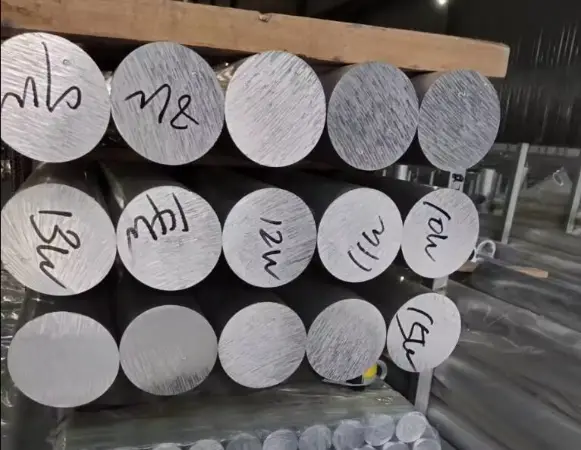

15CrMo Round Bar 15CrMo Alloy Steel Round Bar

FOB Reference Price: Get Latest Price

Description: 15CrMo round bar is a low alloy high-strength steel, executed according to the standard GB/T 3077-2006, and 15CrMo round steel has high thermal strength at high temperatures( δ B ≥ 440MPa) and oxidation resistance, with certain hydrogen corrosion resistan...

Technology: Hot Rolled, Cold Draw, Forge

Available Size: Diameter: 8mm - 650mm, Length: 1m - 12m or customized

Processing Service: Cutting, Whittling, Grinding, Drilling, Boring, Stretching,etc

15CrMo Round Bar Description

15CrMo round bar is a low alloy high-strength steel, executed according to the standard GB/T 3077-2006, and 15CrMo round steel has high thermal strength at high temperatures( δ B ≥ 440MPa) and oxidation resistance, with certain hydrogen corrosion resistance. Due to the high content of Cr, C, and other alloying elements in 15CrMo round steel bar, the quenching tendency of the steel is more obvious, and the weldability is poor.

15CrMo alloy steel round bar adopts advanced steel production technology, which is achieved through high-temperature hot rolling or forging to have a uniform microstructure and delicate grains. This manufacturing process ensures the stability and reliability of 15CrMo round steel, and can fully leverage its performance advantages during use. 15CrMo round steel is widely used in petrochemical industry, shipbuilding, nuclear power plant, boiler, pressure vessel and other industries. It can be used to manufacture various key components such as pipelines, valves, and connectors, as well as important equipment such as high-temperature and high-pressure equipment and safety valves.

15CrMo forged round/forged products can be customized with various processing techniques such as cold drawing, cold drawn flat steel, cold drawn irregular steel, etc., as well as heat treatment, round steel hollowing, round steel cutting, round steel straightening, round steel peeling, etc., and can be manufactured according to different user needs with specified quality and performance.

15CrMo Round Bar Datasheet

| Grade | 15CrMo |

|---|---|

| Standard | GB/T 3077-2006 |

| Diameter | 5-120mm or as required |

| Length | 300mm-1000mm and customized. |

| Surface | Black, Pickled, Mill, Poilshed |

| Technique | Electroslag remelting and Heat treatment |

| Trade Terms | EXW,FOB,CIF CFR |

| Loading Port | Shanghai port, Tianjin port, Qindao port |

| Packing Detail | Standard export package:Wooden pallet +paperboard +steel strip (Customized requirements are accepted) |

| Delivery time | 1.Usually,within10-20days after receiving deposit or LC. 2.According to the order quantity |

| Samples | Free samples are provided but the fright is borne by the buyer |

15CrMo Round Bar Chemical composition

| Element | C | Si | Mn | P | S | Ni |

|---|---|---|---|---|---|---|

| 15CrMo | 0.12%-0.18% | ≤0.5% | 0.40%-0.70% | ≤0.035% | ≤0.035% | ≤0.030% |

| Cr | Mo | Cu | ||||

| 0.8%-1.1% | 0.15%-0.25% | ≤0.03% |

15CrMo Round Bar Mechanical Properties

| Grade | Tensile strength σb (MPa) | Yield strength σs (MPa) | Elongation δ5 (%) | Hardness(HBW) |

|---|---|---|---|---|

| 15CrMo | 440-640 | 235 | 21 | ≤179 |

Equivalent Grade of 15CrMo Round Bar

| China | Japan | Germany | USA | France | |||||

|---|---|---|---|---|---|---|---|---|---|

| Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade |

| GB | 15CrMo | JIS | SCM415 | DIN | 16CrMo44 / 1.7337 | ASTM | A387Gr12 | NF | 12CD4 |

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Leave a Message