Welcome to BBN Steel Materials Factory

42CrMo Alloy Steel Round Bar

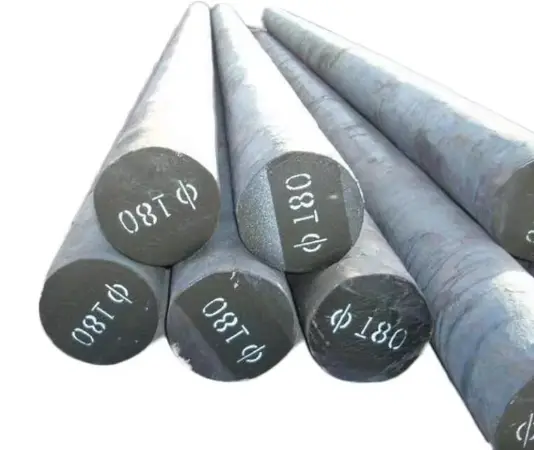

42CrMo Round Bar GB/T 3077 42CrMo Alloy Steel Round Bar

FOB Reference Price: Get Latest Price

Description: 42CrMo round bar is a high-strength alloy steel with excellent mechanical properties and wear resistance. 42CrMo round bar is commonly used to manufacture high-load, high-strength components such as automotive engine crankshafts, gears, and chains.The phy...

Technology: Hot Rolled, Cold Draw, Forge

Available Size: Diameter: 8mm - 650mm, Length: 1m - 12m or customized

Processing Service: Cutting, Whittling, Grinding, Drilling, Boring, Stretching,etc

42CrMo Alloy Steel Round Bar Description

42CrMo round bar is a high-strength alloy steel with excellent mechanical properties and wear resistance. 42CrMo round bar is commonly used to manufacture high-load, high-strength components such as automotive engine crankshafts, gears, and chains.

The physical properties of 42CrMo round bar include density, melting point, and thermal expansion coefficient. The density of this material is 7.85 grams per cubic centimeter, the melting point is approximately 1420-1470 degrees Celsius, and the thermal expansion coefficient is 11.2×10^-6/degrees Celsius. These physical properties make 42CrMo round bar have good stability and reliability under high temperature and high pressure environments.

The chemical composition of 42CrMo round bar mainly includes carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), chromium (Cr), molybdenum (Mo) and other elements. Among them, the content of carbon is 0.38-0.45%, the content of silicon is 0.17-0.37%, the content of manganese is 0.50-0.80%, the content of phosphorus and sulfur is controlled below 0.035%, the content of chromium is 0.90-1.20%, and the content of molybdenum is 0.15-0.25%. The control of these chemical components can improve the strength and wear resistance of 42CrMo round bar.

42CrMo round bar is widely used in the industrial field. 42CrMo alloy round bar is commonly used in the manufacture of automotive engine crankshafts. Due to the high frequency and high strength of rotation required for automotive engine crankshafts, it needs to have high strength and wear resistance. 42CrMo round bar is one of the ideal materials that meet these requirements.

42CrMo round bar is also commonly used in the manufacture of gears, chains, and other components. Gears are common components in mechanical transmission systems that require high loads and wear resistance. The high strength and wear resistance of 42CrMo round bar make it an ideal choice for manufacturing gears.

42CrMo Alloy Steel Round Bar Datasheet

Steel Grade: 42CrMo Alloy steel round barTechnique: Hot Rolled/ Forged/ Cold drawn

Application: Tool Steel Bar

Processing:

Heat treatment: soft annealing, normalising, isothermal, spheroidising and stress relieving treatments, quenching and tempering Peeling

Tolerance: ±1%

Diameter: 6mm-800mm

Length: 1-12m

Shape: Round. Square. Rectangular

Application

* Automatic lathe processing, metal stamping parts processing;

* Electronic industry, optical fiber connector, optical disc drive, scanner, medical equipment;

* Household appliances, instrumentation industry;

* Office equipment (computers, photocopiers, cameras, fax machines, etc.);

* Watch components, glasses;

* Electronic terminal pin, timer, carburetor;

* Decorations, light ornaments, cars, motorcycles, chains;

* Clean car sweepers and toys;

* Pens, handbag accessories, belt buckles, fishing gear, etc .;

* Studs, screws, nuts, pipe joints, spring seats, etc.

42CrMo Alloy Steel Round Bar Chemical composition

| Element | C | Si | Mn | P | S | Ni |

|---|---|---|---|---|---|---|

| 42CrMo | 0.38%-0.45% | 0.17%-0.37% | 0.50%-0.80% | ≤0.035% | ≤0.035% | ≤0.030% |

| Cr | Mo | Cu | ||||

| 0.9%-1.2% | 0.15%-0.25% | ≤0.030% |

42CrMo Alloy Steel Round Bar Mechanical Properties

| Grade | Yield strength σb (MPa) | Tensile strength σs (MPa) | Elongation δ5 (%) | Hardness(HBW) |

|---|---|---|---|---|

| 42CrMo | ≥1080 | ≥930 | ≥12 | ≤217 |

| Reduction of area ψ (%) | Impact energy Akv (J) | Impact toughness value α KV (J/cm2) | ||

| ≥45 | ≥63 | ≥78(8) |

Equivalent Grade of 42CrMo Alloy Steel Round Bar

| China | Japan | Germany | USA | ||||

|---|---|---|---|---|---|---|---|

| Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade |

| GB | 42CrMo | JIS | SCM440 | DIN | 42CrMo4 / 1.7225 | AISI | 4140/4142 |

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Leave a Message