Welcome to BBN Steel Materials Factory

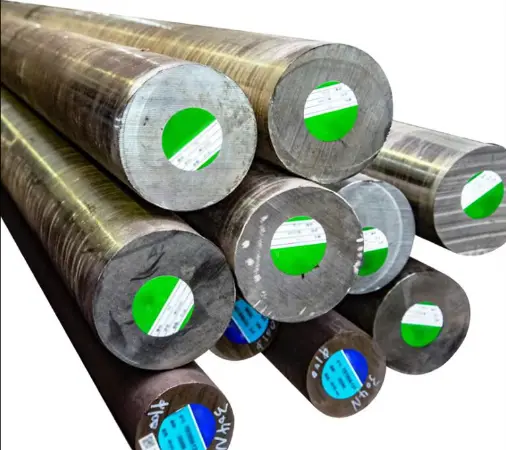

20CrMo Round Bar

20CrMo Round Bar | 20CrMo Alloy Structural Round Steel

FOB Reference Price: Get Latest Price

Description: 20CrMo Round Bar is a high-strength alloy structural steel, which complies with the standard GB/T 3077. 20CrMo round steel has high hardenability, no temper embrittlement, good weldability, little tendency to form cold cracks, good machinability and cold ...

Technology: Hot Rolled, Cold Draw, Forge

Available Size: Diameter: 8mm - 650mm, Length: 1m - 12m or customized

Processing Service: Cutting, Whittling, Grinding, Drilling, Boring, Stretching,etc

20CrMo Round Bar Description

20CrMo Round Bar is a high-strength alloy structural steel, which complies with the standard GB/T 3077. 20CrMo round steel has high hardenability, no temper embrittlement, good weldability, little tendency to form cold cracks, good machinability and cold strain plasticity. 20CrMo is usually used in the quenching and tempering state, mainly for the manufacture of high-pressure pipes, fasteners and advanced carburized parts such as gears and shafts, which work in non-corrosive media and at working temperatures below 250℃.

20CrMo Alloy Structural Round Steel has good comprehensive mechanical properties and low temperature toughness, with a wide range of applications and good processing properties. 20CrMo round steel bar also has good wear resistance, corrosion resistance and fatigue resistance, which can extend the service life of parts. 20CrMo round bar is widely used in machinery, automotive, petrochemical and other fields.

20CrMo Alloy Steel Round Bar requires heating, forging, cooling, heat treatment and other processes. The forging temperature range is wide, and the deformation resistance is low, which is conducive to processing and forming. The chemical composition of 20CrMo alloy steel round bar mainly includes carbon, silicon, manganese, chromium, molybdenum and other elements. The content and proportion of these elements have a significant impact on the properties of the steel.

20CrMo Round Bar Datasheet

Out Diameter:20mm-610mm

Length:4m-12m or as required

Thickness tolerance: ±0.1mm

Technique: Hot rolled

Surface Treatment: Clean, blasting and painting according to customer requirement

20CrMo Round Bar Chemical composition

| Element | C | Si | Mn | P | S | Ni |

|---|---|---|---|---|---|---|

| 20CrMo | 0.17%-0.24% | 0.17%-0.37% | 0.40%-0.70% | ≤0.035% | ≤0.035% | ≤0.030% |

| Cr | Mo | Cu | ||||

| 0.8%-1.1% | 0.15%-0.25% | ≤0.03% |

20CrMo Round Bar Mechanical Properties

| Grade | Yield strength σb (MPa) | Tensile strength σs (MPa) | Elongation δ5 (%) | Hardness(HBW) |

|---|---|---|---|---|

| 20CrMo | ≥685(70) | ≥885(90) | ≥12 | ≤197 |

| Reduction of area ψ (%) | Impact energy Akv (J) | Impact toughness value αkv (J/cm2) | ||

| ≥50 | ≥78 | ≥98(10) |

Equivalent Grade of 20CrMo Round Bar

| China | Japan | Germany | USA | ||||

|---|---|---|---|---|---|---|---|

| Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade |

| GB | 20CrMo | JIS | SCM420 | DIN | 18CrMo4 / 1.7243 | ASTM | 4120 |

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Leave a Message